Axial Seals

TM Series Seals

Tyton axial seals are designed for operators to have a higher degree of control which leads to increased durability and performance. Fematics Canada Inc. has spent years developing a composite sealing ring that is very efficient and has low maintenance requirements depending on the working conditions at site You can find these types of mechanical seals in all turbine systems including:

- Francis Type Turbines

- Kaplan type Turbines

- Pump Turbines

- Pelton Type Turbines

Conventional axial seal designs use springs as the initial closing force and then rely on turbine pressure to keep the seal closed. Alternatively, compressed air can also be used as the closing medium of the seal thus guaranteeing 100% adjustability to find the perfect balance.

Under the correct operating conditions, the axial seal is designed to achieve the perfect balance resulting in direct maintenance savings and more generating time for hydro dam owners and operators

Operational Limits

| Max. Turbine operating pressure | Up to 150PSI (1000kPa) |

| Recommended barrier pressure | 10PSI (70kPa) above turbine pressure |

| Max. Shaft diameter | Unlimited |

| Recommended water quality | 50-75 microns |

| Radial shaft dislocation allowance | +/- 3mm (0.120 inches) |

| Axial shaft dislocation allowance | Based on customer requirements |

Working Principle

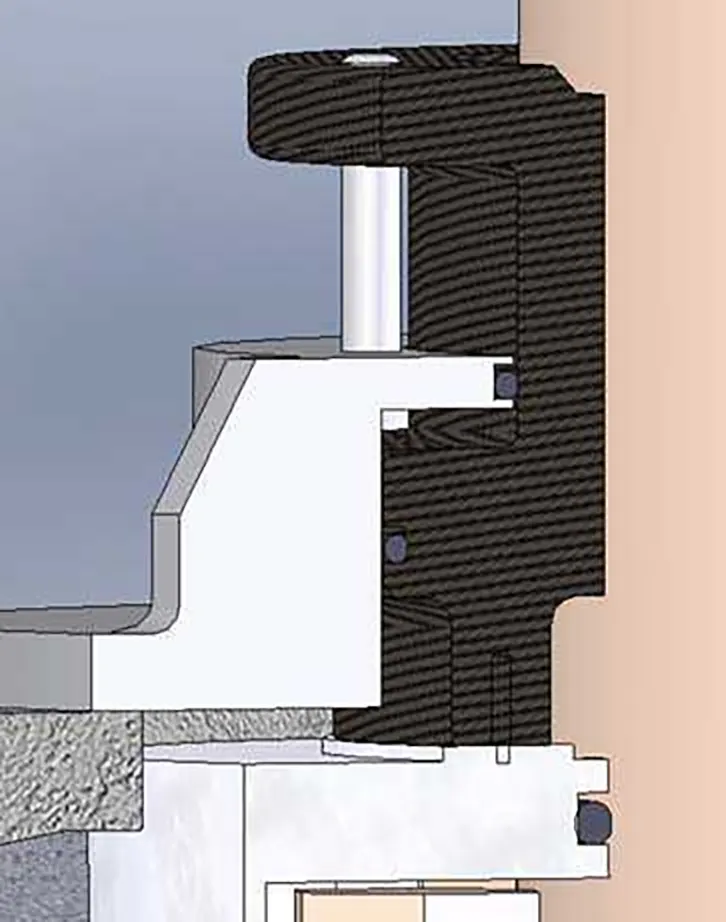

With the axial type seal, the sealing action takes place between two mating rings; one stationary, the sealing ring, and the other rotating with the shaft, the seat ring. The axial seal is designed to provide maximum control of the seal’s behavior to ensure optimal performance. Not too tight that the sealing face will be wear quicker, not too loose that water will leak out of the seal. This avoids the wearing of the turbine shaft and eliminates the need of a costly shaft sleeve.

For best performance, it is required that the sealing ring is held in close contact with the seat ring. Most designs use compression springs to push down the sealing element. This type of seal closing design does not take in consideration variability in the turbine pressure, as the springs always apply the same amount of pressure on the mating faces. Today, this type of design is still very popular in these types of seals.

Fematics Canada Inc. has developed a unique alternative to the traditional design in which compressed air is used instead. This design is much simple for installation, maintenance and daily operation, as you have no spring type arrangement all around the seal. The greatest advantage is that this type of configuration makes the seal fully controllable.

Combined with a differential pressure regulator, located on a control panel, the pressure inside the air chamber can vary with the turbine pressure, so the seal is always closed at the proper pressure. Not too tight that the sealing face will be worn quicker, not too loose that water will seep out of the seal. Controlling and adjusting the sealing position is a great advantage when the pressure conditions at site are changing. The operator can then control the sealing wear, and also the rate of leakage, wich makes this type of seal a fully controllable, leak proof mechanical seal.

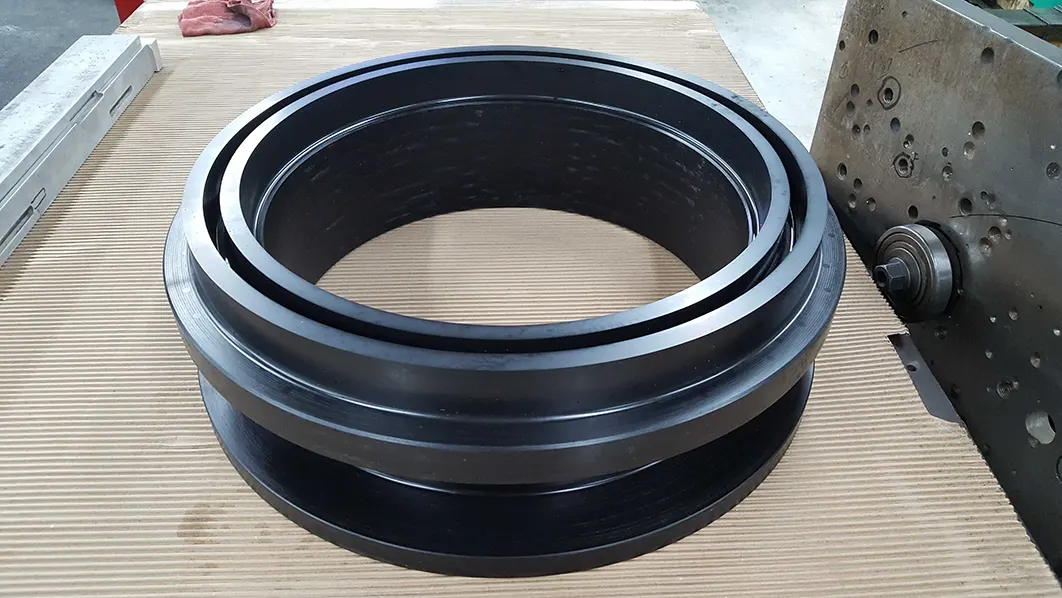

470mm Sealing Ring

Where can we find them:

We have been making our proprietary composite seals for more than twelve (12) years now. Our seals are installed all around the world:

| Canada | Ireland | Argentina |

| Brazil | Guinea | Buthan |

| United States of America | New Zealand | India |

Quick overview of the Tyton-Fematics Axial Seal closing principle

Our sealing rings are manufactures in our Montreal based plant, and can be custom fabricated to your demands. We offer long wear allowance (12mm) on our sealing face, wich means many years of maintenance free operations.

2050mm Sealing Ring

Sealing materials

Composite Sealing Ring TJ400/450

After extensive R&D, we have designed the perfect materials to be used in our Axial type seals. The Tyton Composite Sealing Ring is the next generation of sealing face, providing an extremely flexible surface, while being a very long-lasting material.

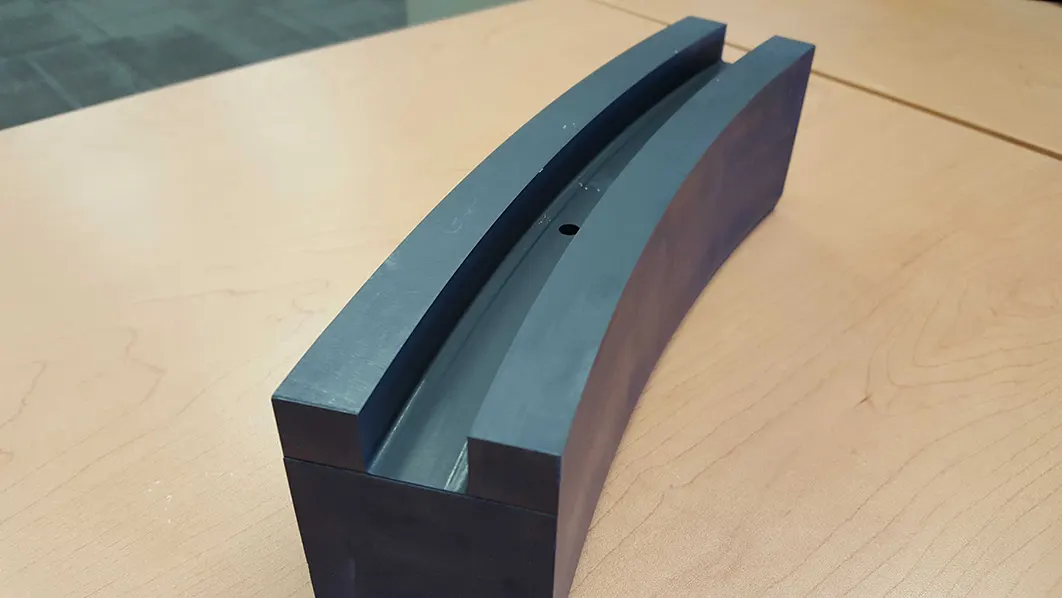

Base Material (TJ400) / Composite Buildup (TJ450)

The other advantage of our composite sealing rings is that after providing many years of incredible face sealing, the worn-out composite can be machined off and recast to the original specifications. We can refurbish your old sealing ring for a fraction of the price of a complete replacement. We recommend that for each time you change/refurbish two (2) sealing rings, the seat ring be sent for inspection, it can be re-lapped or will need to be replaced, depending on wear and general condition.

We recommend that for each time you change/refurbish two sealing rings, the seat ring should be sent for inspection, it can be relapped or will need to be replaced, depending on wear and general condition.

2050mm Composite Sealing Ring used in a pump turbine application

Our sealing rings are manufactured out of two materials. The base materiel (TJ400), a very solid glass fiber and resin mix, that can be basted out in many different shapes, to reflect the different turbine outline, and to match the different mechanical seal principles we use. The composite buildup (TJ450), is out of our proprietary carbon mix, to offer you with a high performance, extremely long-lasting sealing surface.

View of typical wear length of our TJ450 composite buildup

Carbon Segments TG615

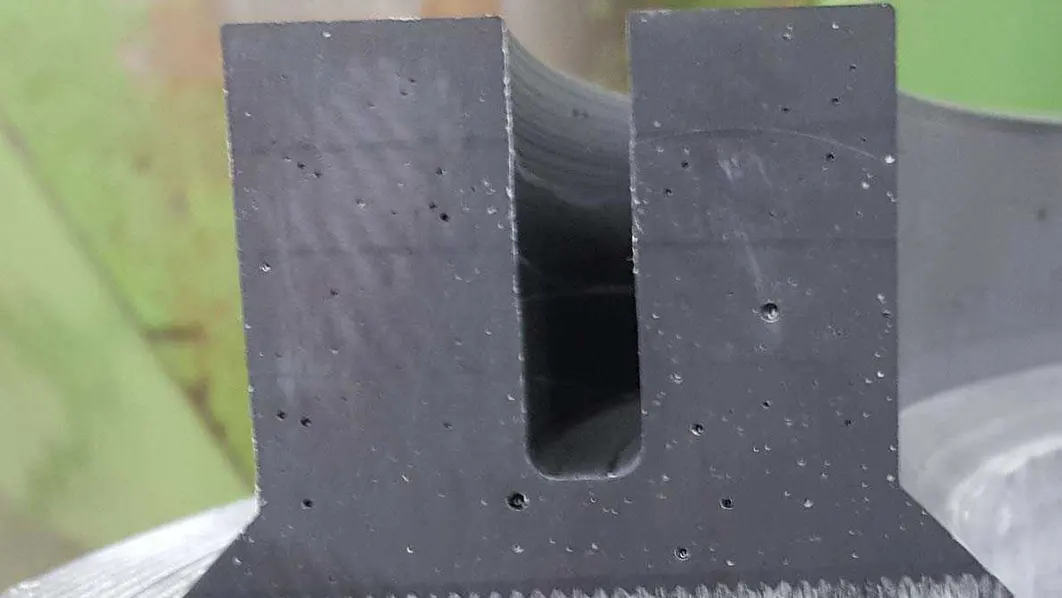

We only use high-grade carbon, to manufacture our carbon segments. All of our carbon segments are manufactured in house at our Montreal based plant, which allows us to keep control on our manufacturing and ensure a quick turnaround time for our customers.

A small hole, located on the top of the carbon segment, allows water to flow to the sealing surface, providing lubrication and cooling to the mating surfaces.

TG615 Axial seal type carbon segment

TG615 Axial seal type carbon segment

Fematics Canada Inc. offers 1/2’’ (12mm) of wearable material and a high precision surface finish (machining tolerances within 12 microns (0.00005’’), and easy to read installation identification on each of our carbon segments.