Radial Seals

TR Series Seals

Fematics radial seals offer economical, long lasting performance on turbines with pressures up to 60 PSI (4 bar or 400 Kpa). This simple design has proven to be an efficient, cost effective sealing solution on a variety of equipment for over 100 years. Compared to traditional stuffing boxes with packing, the radial seal option offers important savings on maintenance, downtime and energy losses due to friction.

Our seals are reliable, simple to install, self-adjusting and easy to operate and maintain. Tyton-Fematics radial seals can be split and custom designed for any customer requirements. You can find these types of mechanical seals in :

– Hydroelectric Turbines

– Boat Propeller Shafts

– Rudderstock

– Large Water Pumps

– Chemical Pumps

– Boat Hauls

Operational Limits

| Max. Turbine operating pressure | Limited by space available (height) |

|---|---|

| Recommended barrier pressure | 3-5 PSI (20-35 kPa) above turbine pressure |

| Max. Shaft diameter | 10 feet (3 meters) |

| Recommended water quality | 25 microns |

| Radial shaft dislocation allowance | +/- 3mm (0.120 in) |

| Axial shaft dislocation allowance | Unlimited |

Working Principle

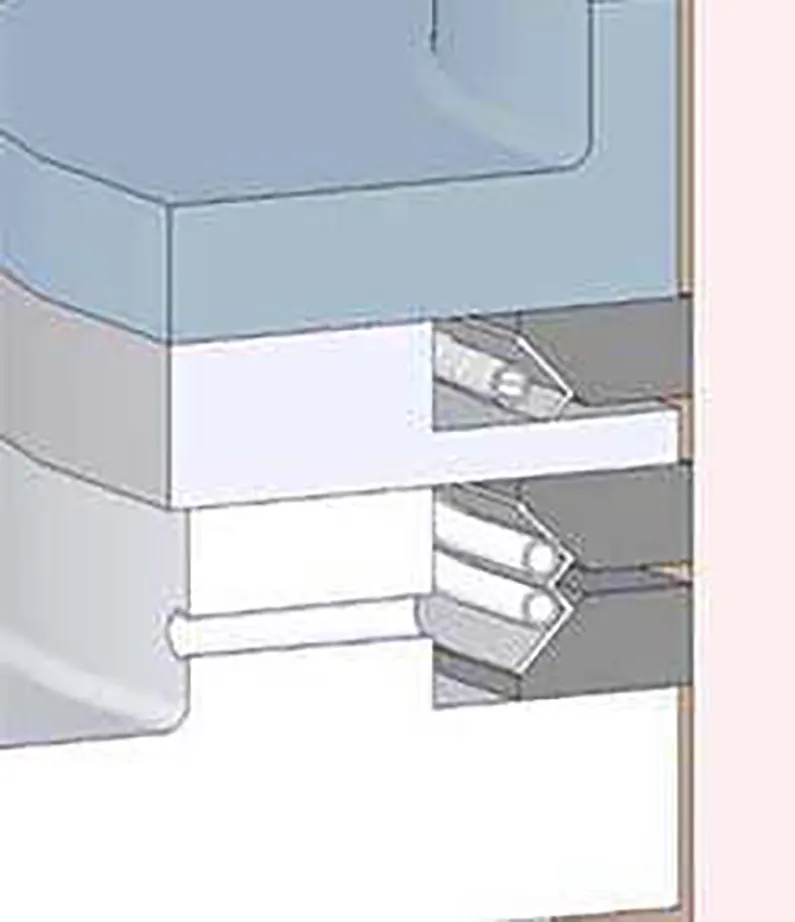

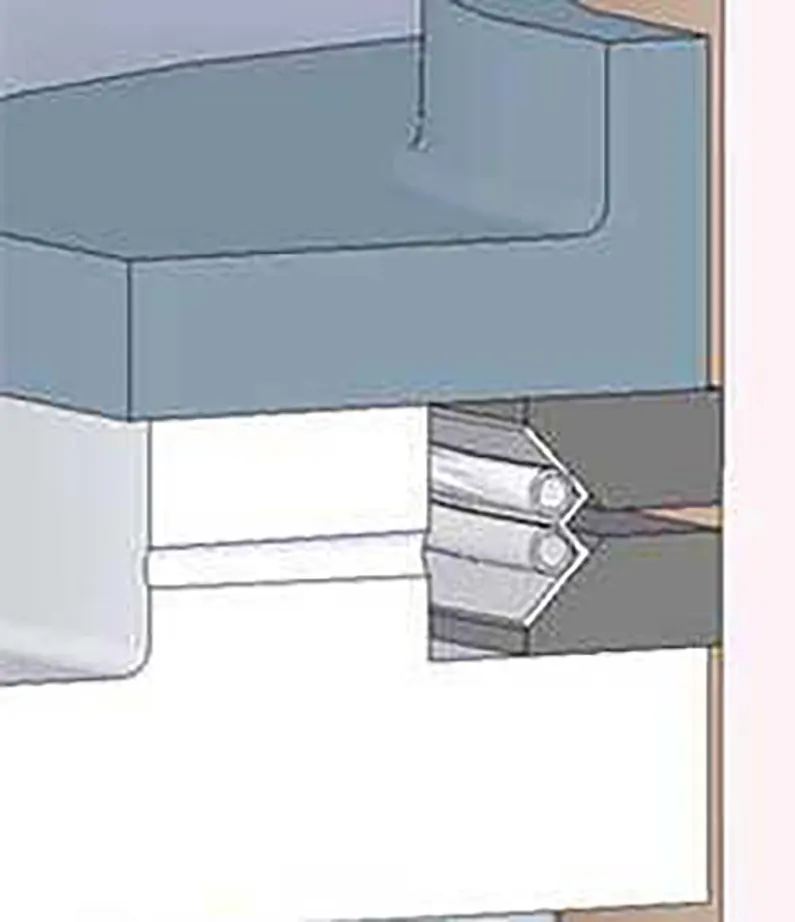

Our radial seal design is primarily based on turbine pressure (pressure under the head cover). Two (2) or more carbon rings provide the sealing action against the turbine/pump shaft, in the radial direction and axially against the internal faces of the seal chambers. Higher head pressure will necessitate more rows of carbons.

Our TR200 series seal contains two rows of carbons and has a maximum turbine pressure of 30 PSI, where as the TR300 series contains three rows of carbon and has a maximum turbine pressure of 60 PSI.

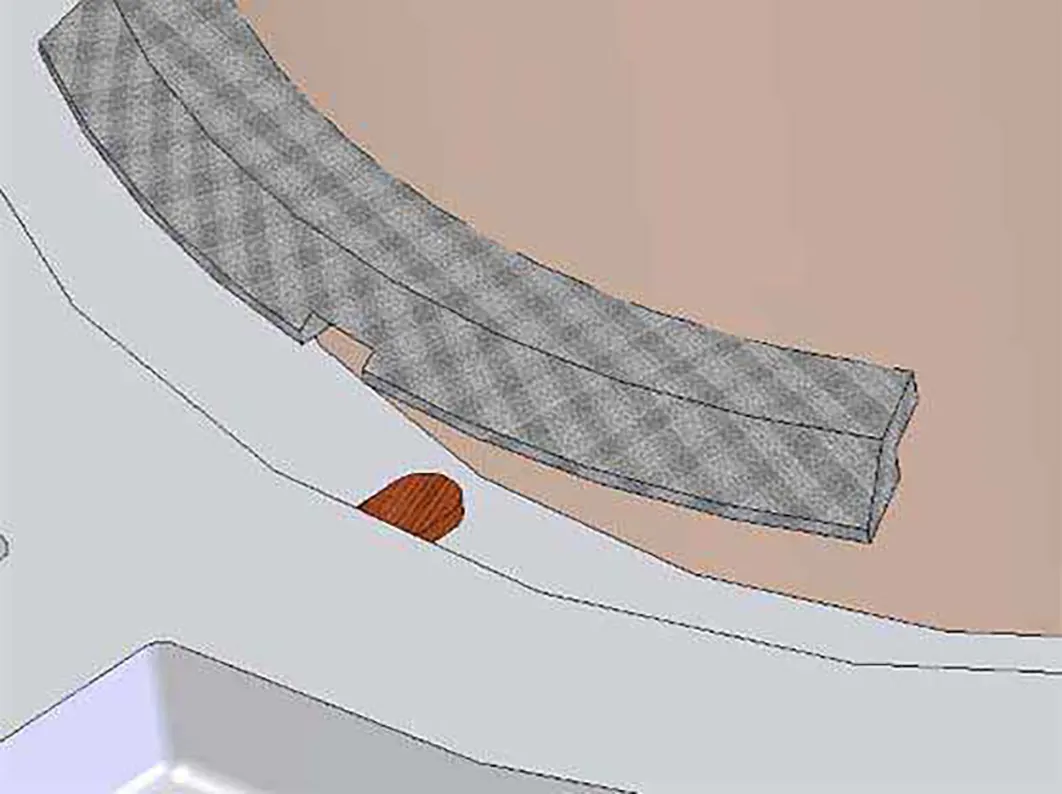

The carbon segments have a small pocket machined into them, to allow access to an alignment pin in

order to prevent them from turning with the rotating shaft.

TR200 series cutaway

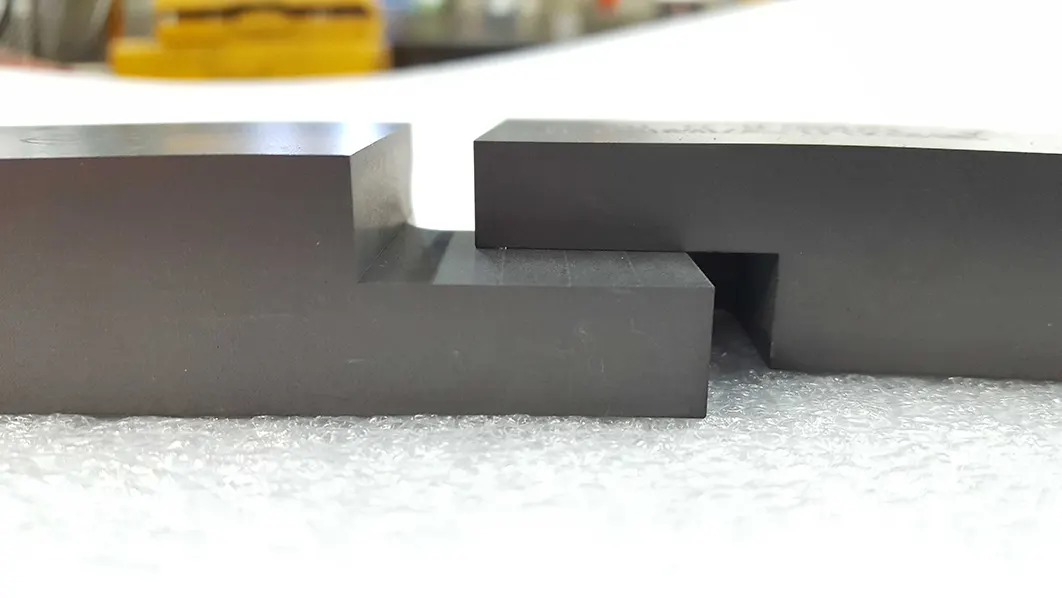

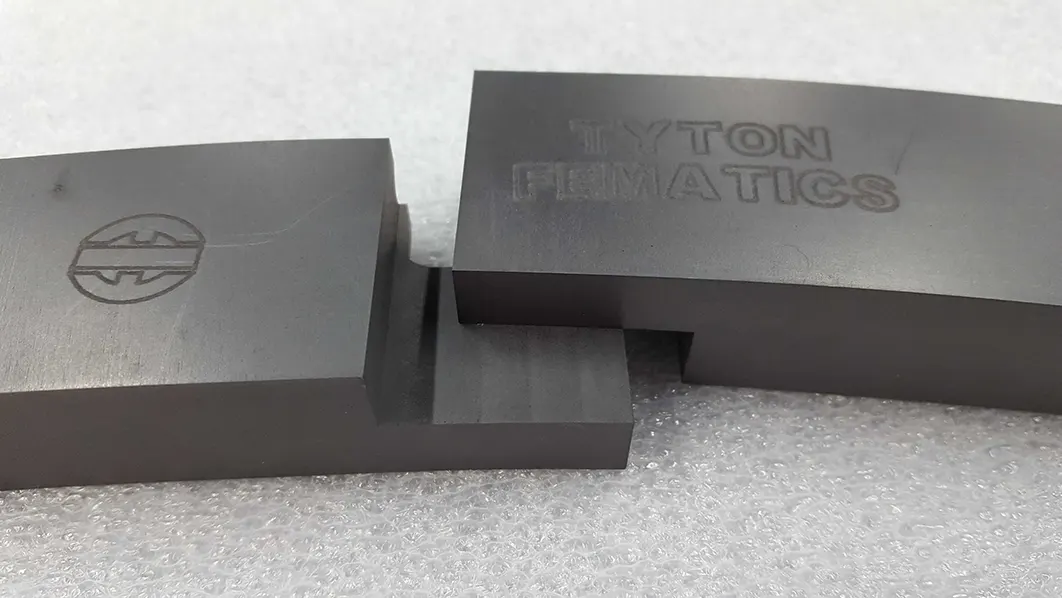

Carbon segment with alignment pin pocket

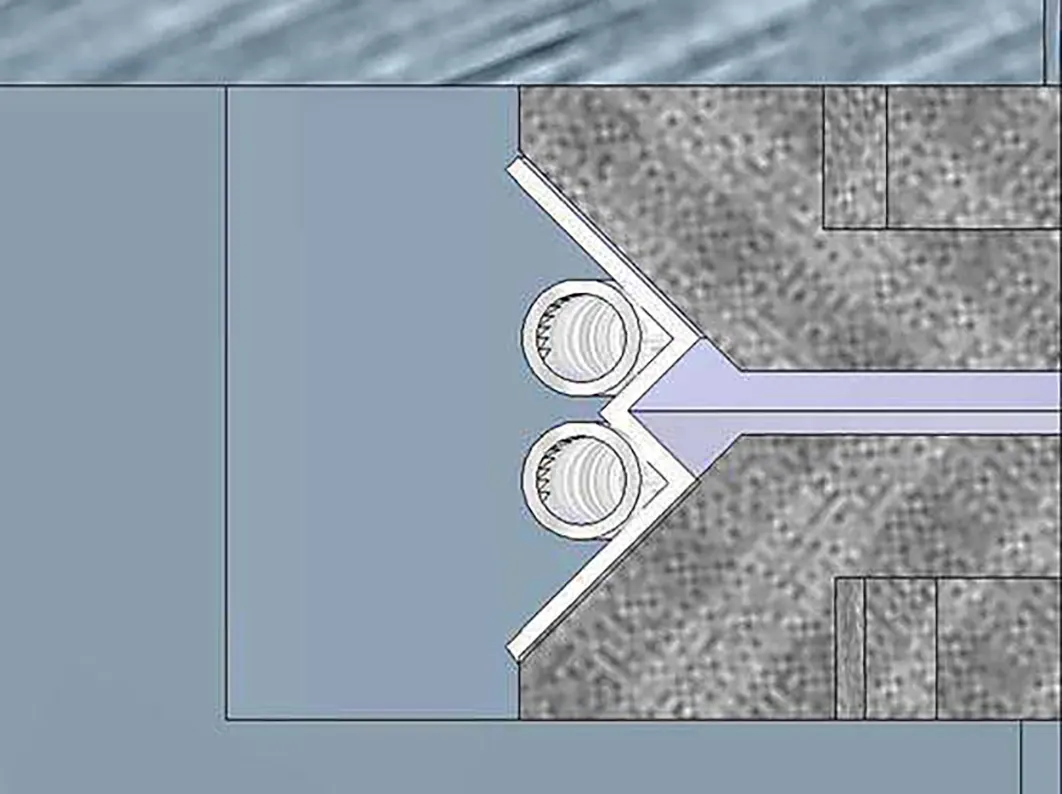

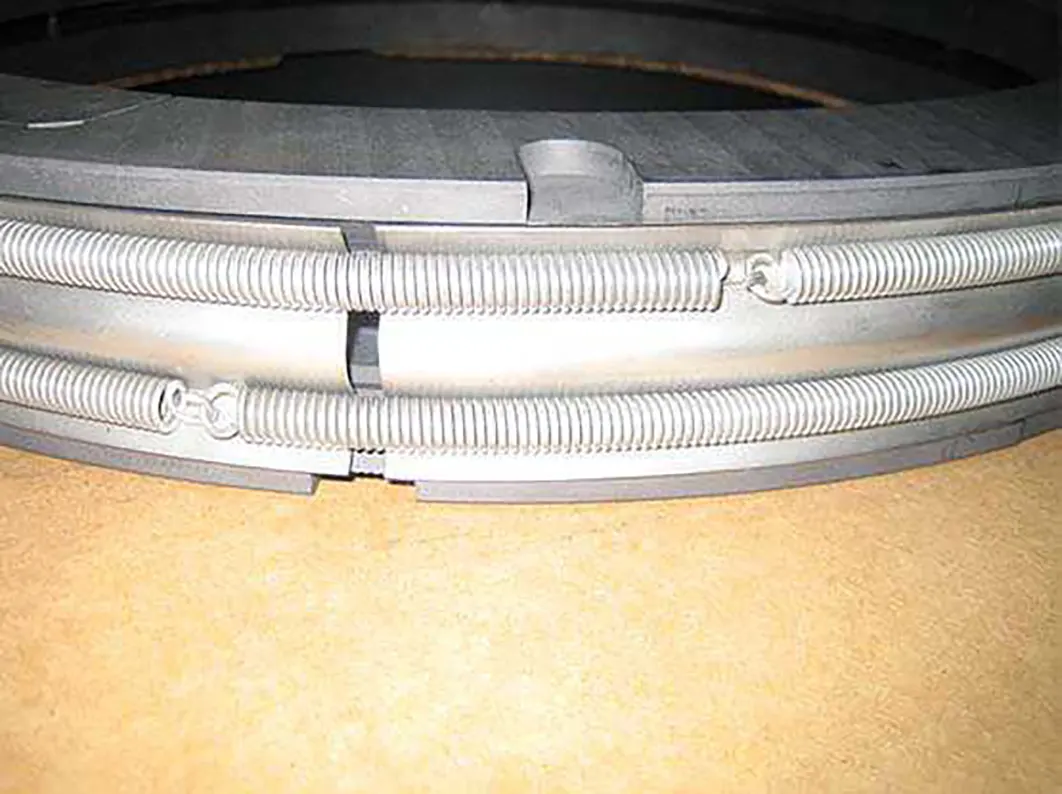

Typical assembly of garter carbon, garter springs and pressure segments inside chamber

Where to find them

With over 600 units fabricated by Fematics, our Tyton radial seals can be found in many areas all around the world.

| Canada | China | Korea |

|---|---|---|

| Brazil | Sri lanka | Russia |

| Panama | Finland | Pakistan |

| India | Norway | Indonesia |

| United States of America | El Salvador | Ireland |

| Turkey | Columbia | Iceland |

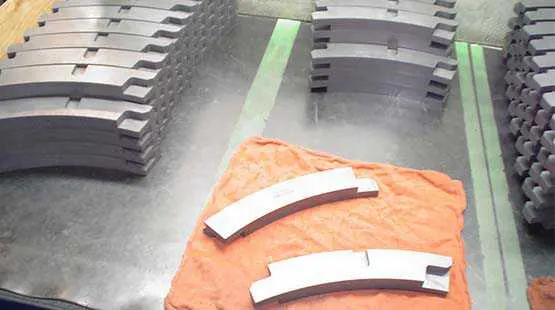

TR300 series cutaway

The carbon segments have a small pocket machined into them, to allow access to an alignment pin in order to prevent them from turning with the rotating shaft.

Carbon segment alignment pin

Garter springs with pressure rings (segments) apply the forces necessary to position the carbon segments correctly in both directions. The garter springs act only on start-up, as the actual sealing

pressure is obtained by the lubrication water pumped into the seal (10 times the force of the garter spring). Clean water is injected between the surfaces to lubricate and cool the sealing elements, minimizing wear and providing a long-lasting sealing solution. The water plays an important role in cleaning the sealing surface by pushing impurities out of the seal.

The cover of the seal is designed to act as a reservoir and additional inlets can be provided to maintain a constant supply of water to the top sealing element preventing dry running. Outlets are also installed in the seal housing to remove any excess water. Injected water pressure and flow are very important for radial type seals. Water pressure will provide just enough force to push the carbon segment on the surface of the shaft to provide the sealing force and the water flow, which varies with the speed of the shaft, must be calculated to make sure enough water is pumped into the seal versus the speed of the shaft. Sometimes, more than one water inlet may be necessary for high-speed turbines and depending on the seal size.

Two row assembly

Carbon Segments

We only use high-grade carbon to manufacture our carbon segments. All of our carbon segments are manufactured in house in our Montreal based plant, which allows us to keep control on our manufacturing and ensure a quick turnaround time for our customers.

We use a unique finger/pocket design that ensures a continuous sealing surface and ease of installation compared to wedge-type carbon segments.

We use a unique finger/pocket design, that ensures a continuous sealing surface, and ease of installation compared to wedge-type carbon segments.